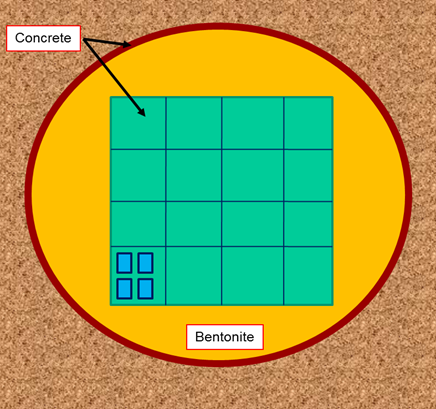

Bentonite is an important component in many designs for radioactive waste repositories. The plasticity, swelling capacity, colloid filtration, low hydraulic conductivity, high retardation of key radionuclides and stability in relevant geological environments all make bentonite an ideal barrier/buffer material in the engineered barrier system (EBS). But, the longevity of bentonite—especially the potential for waste canister sinking/settling in bentonite (or bentonite-sand mixtures) over long timescales—has been little studied. In the paper by Alexander et al. (2017) first steps forward have been taken to employ field studies to understand the deformation behaviour in bentonites. This text is largely based on this paper published in Geosciences. Waste package sinking process becomes the more important the more heavy waste packages are considered. Especially in Low and Intermediate-level Waste (L/ILW) repository designs (cf. Figure 1), concrete waste packages are used in large volumes, which causes higher loads on the bentonite surrounding them than in many HLW disposal concepts.

Figure 1: An example waste cavern design for a cementitious L/ILW (low- and intermediate-level waste) repository. Waste containers (blue, typically 200 L metal drums filled with waste and a cement grout) are encased in concrete boxes (green) which are usually backfilled with more cement grout. The boxes are then protected by industrial bentonite to minimise groundwater interaction with the waste. The tunnel walls may also be supported by concrete tunnel liners. (image from Alexander et al. 2014)

The focus of this study was the assessment of the long-term performance of bentonite, in particular, creep and related potential lateral movement of bentonite under and around waste packages.

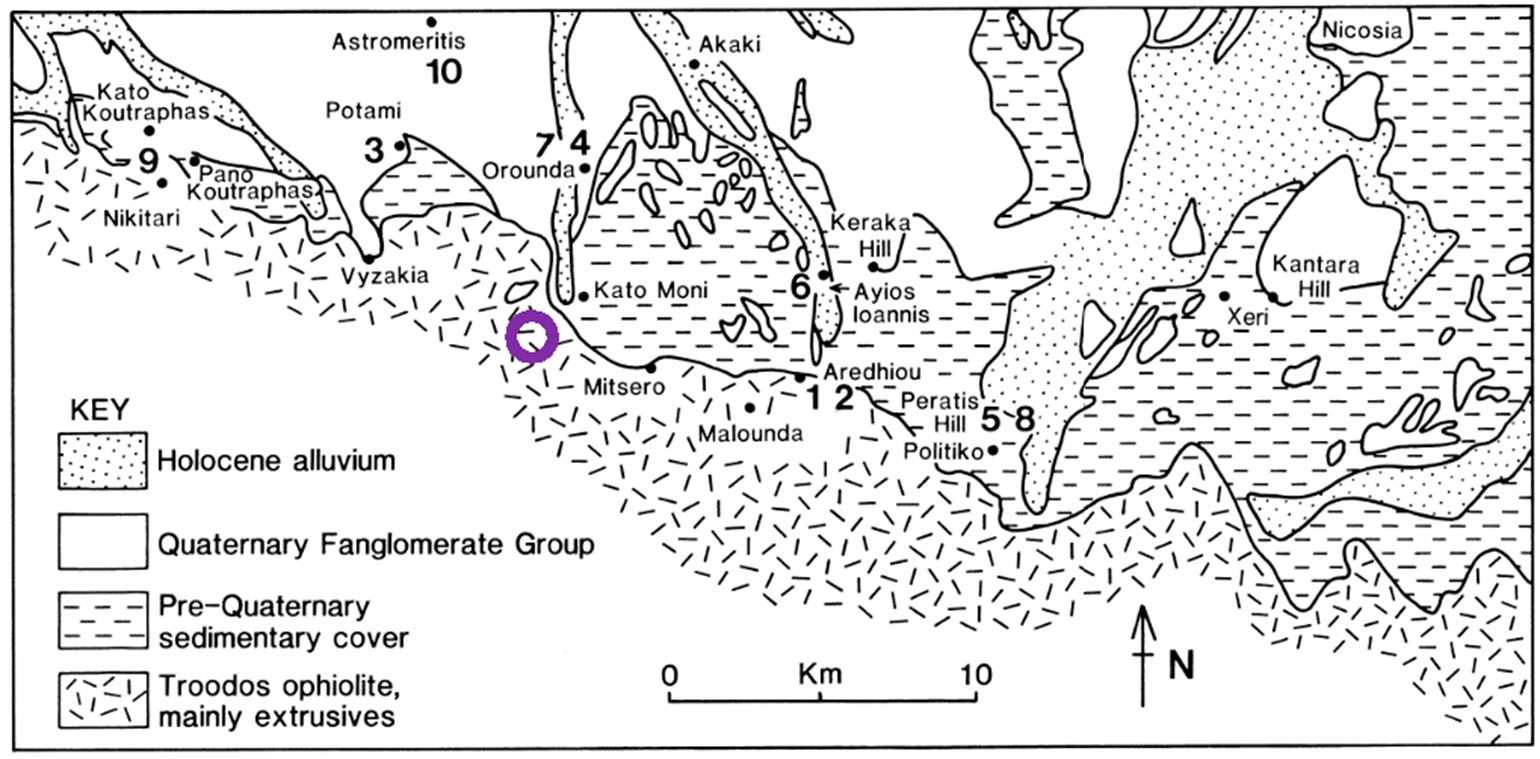

Investigations were undertaken at Cyprus, Kato Moni bentonite quarry site (Figure 2). Kato Moni is located north of Troodos mountains (Figure 3).

Figure 2: Quarry face looking north-west at Kato Moni drilling site showing exposed bentonite (reddish brown) and overlying limestone cap rock in the background. (Photo H. Reijonen)

Figure 2: Quarry face looking north-west at Kato Moni drilling site showing exposed bentonite (reddish brown) and overlying limestone cap rock in the background. (Photo H. Reijonen)

Figure 3: Simplified geological map of the study area (purple circle). (image from: Poole & Robertson 1989)

At Kato Moni site bentonite occurs between the underlying pillow lavas of the Cyprus ophiolite complex and overlain by limestone (Figure 3). In the area, erosional processes have produced an undulating topography where limestone cap rocks are found on top of hills. Bentonite occurs directly under them and are often exposed on the hill sides and valley bottoms.

Kato Moni site was studies by drilling three holes, two through the limestone cap rock and one directly in the bentonite (valley bottom), and sampling them for thorough mineralogical, chemical and physical analyses. Special thin sections were made to study the internal structures in the bentonite at variable depths.

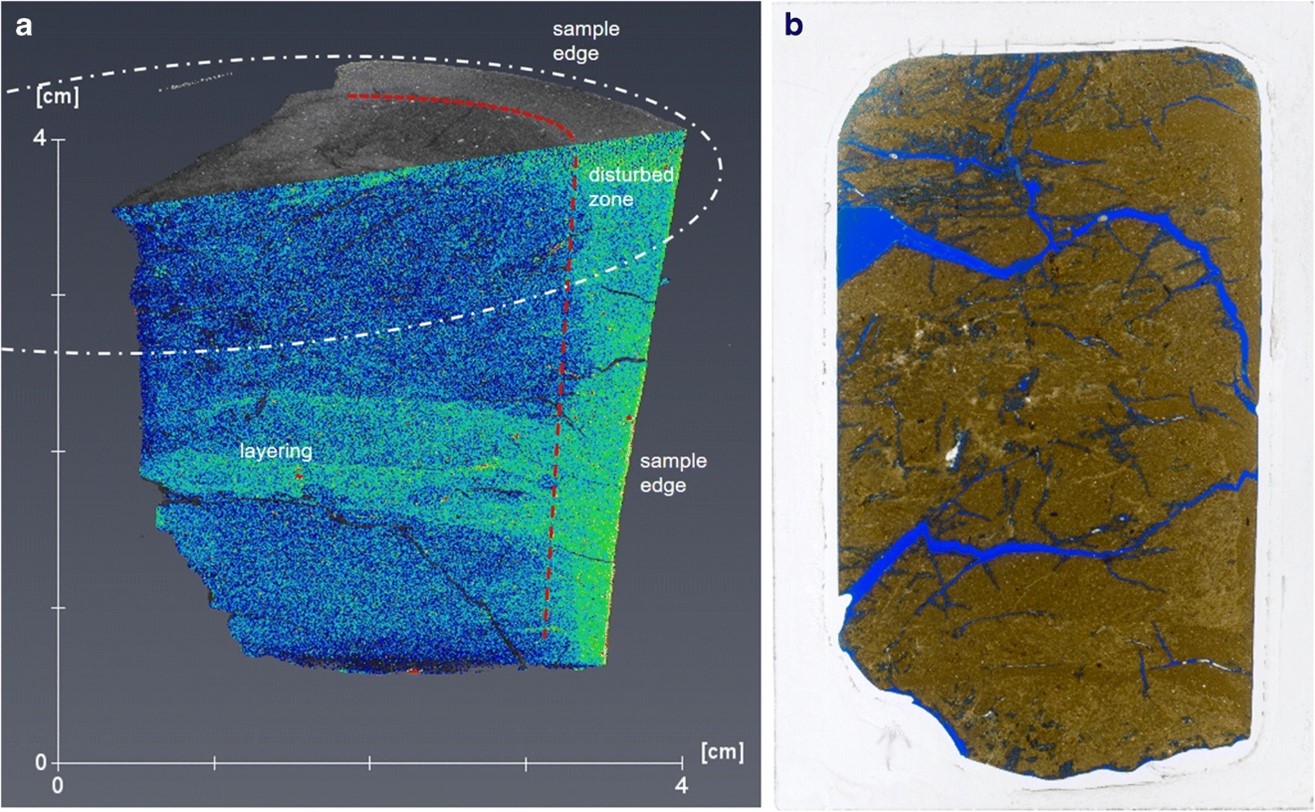

In the textural studies disturbances caused by handling (e.g. bentonite relaxation after retrieval and tensional cracking due to sample drying) could be differentiated from the in situ textures. Observations of interest regarding bentonite deformation and preservation of primary structures are that:

- the pattern of faulting indicates that there has been some lateral shear along the bedding planes,

- there is evidence of some multi-directional shear in the bentonite, especially, the network conjugate, steeply-inclined, micro-faults that tail-off into shear fabrics suggest movement in at least two directions¾e., movement unlikely to be gravitationally induced.

These observations support the preliminary conclusion that the loading by the overlying limestone could be the source of deformation and thus provide an analogy to the loading processes in the repositories.

The study has been successful as a “prove of concept” on studying the bentonite deformation on natural bentonite sites.

Initial project reported by Alexander et al. 2017 stemd research also regarding sampling of bentonite and tools for better constrain the in situ features of the samples (Reijonen et al. 2020). Utilising micro X-ray tomography, samples can be investigated non-destructively revealing both in situ textures, as well as deformations caused by sampling (Figure 4). In addition, deformation is included in the ongoing International Bentonite Longevity (IBL) project, undertaken in Tsukinuno mine, Japan.

Figure 4: A 3D presentation of X-ray tomographic result of Kato Moni bentonite (left) compared to thin section (right) of the same sample (details in Reijonen et al. 2020).